aluminum crucible furnace

spiral furnace

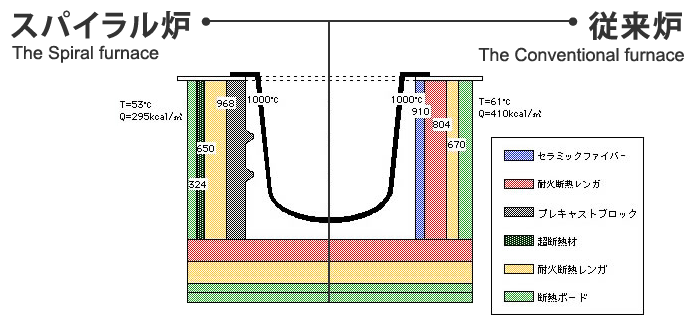

Comparison with conventional furnace

Structural comparison

*Spiral crucible condition is 1 month after replacement.

*Working conditions include die casting, hot charging, and operation for 20 hours or more on weekdays.

Functions and features

Feature.01

spiral furnace

As the flame rotates in a spiral, effective heat is transferred to the entire crucible.

Controls the pressure inside the furnace for optimal combustion.

Conventional furnace

The flame is heading to the exhaust port in about one lap.

Feature.02

spiral furnace

● Speed up temperature rise

Since the flame rotates along the frame guide, the entire crucible is wrapped in flame. By transferring heat to the entire crucible, the heating speed is increased.

Conventional furnace

The flame is circulating only in a part of the crucible, which causes cracking of the crucible.

Feature.03

spiral furnace

●Reduction of defect rate

It eliminates unevenness in melting temperature and leads to uniform product quality.

Conventional furnace

The crucible is locally heated and temperature unevenness occurs.

Feature.04

spiral furnace

Extending crucible life

Since the crucible surface load is uniform, it prevents the load from being applied only to a part of the crucible and extends the life of the crucible.

Conventional furnace

Product specifications

- Furnace body (1 unit)

- Combustion equipment (1 set)

- Control panel (side 1) temperature controller, misfire alarm, blower overload alarm, hot water leak detection alarm

*Detailed usage will be decided through a meeting.

*Crucibles are available separately.

*There are also options such as a heat-retaining lid.