Aluminum continuous melting and holding furnace

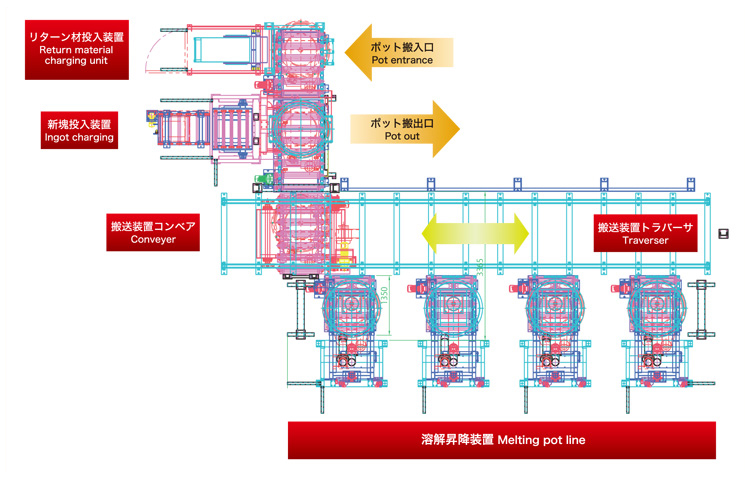

pot melting system

Product features

Comparison with central melting furnace system

1

Central melting furnace system

- "Centralized melting furnace", "Conveyor for ladles", "Hand furnace"Requires 3 separate devices.

- Retaining molten metal during non-operation such as nights and holidayslarge energy loss.

- Dissimilar alloy melting is impossible.

- When adding a die casting machine, it is necessary to install a furnace with a capacity that can handle all the planned number of machines.Generates large losses when updating plans.

- Dangerous work (draining tap work) is required,Risk of water leakage.

2

pot melting system

- "Pot melting furnace" equipped with material input and "hand furnace" in a series of flow from melting to metal distributionOnly 2 separate devices required.

- Efficient dissolution of the required amount in a short time at the required timeand can be quickly supplied to the hand furnace.

- By installing multiple pots,Dissimilar alloys can be melted.

- By installing multiple units, it is possible to adjust the amount of melting according to the production situation.Reduce investment risk.

- Dangerous work (draining tap work) is unnecessary,Operate safely.

Introduction example of pot melting furnace

Specifications/capacity

| pot capacity | Aluminum 350kg/pot |

|---|---|

| melting burner | Heat exchanger burner (250,000kcal/hr) |

| Melting capacity | 350kg/hr |

| LPG basic unit | 0.035 Nm3/kg |

| Grade | Supports 2 types |